Polyvance Plastic Repair & Nitrogen Welding Certification Course | A22PPW

Overview

Unlock the power of nitrogen fusion welding with our Polyvance Plastic Repair Course, designed by Polyvance and Area22 Training Centre. This program addresses the growing need for durable, cost‑effective plastic repairs across automotive, powersports, and industrial sectors.

Course Highlights

- Industry Challenges: Learn why traditional glues and epoxies fall short—high part costs, environmental waste, and weak bonds.

- Polyvance Technology: Master nitrogen plastic welding for true fusion repairs, using Polyvance welders, rods, and adhesives for seamless finishes; understand machine start‑up/shut‑down and safety protocols.

- Material Identification: Hands‑on practice with weld‑testing kits to accurately identify plastics before repair.

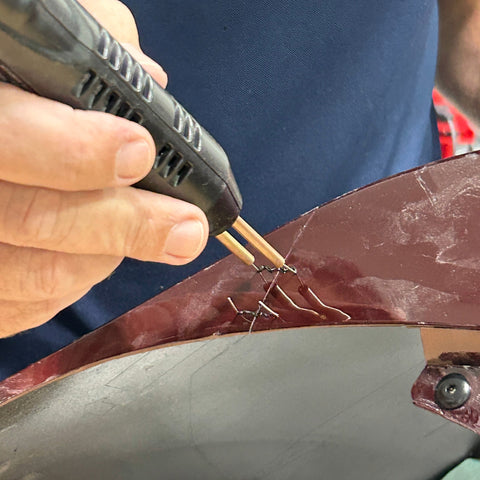

- Repair Techniques: Step‑by‑step methods for repairing bumper tears, broken tabs, flanges, thermoset polyurethane components, and more.

- Applications: Tailored instruction for auto body shops, motorcycle/ATV repair, fleet maintenance, industrial manufacturing, and advanced DIYers.

Hands-on Training & Certification

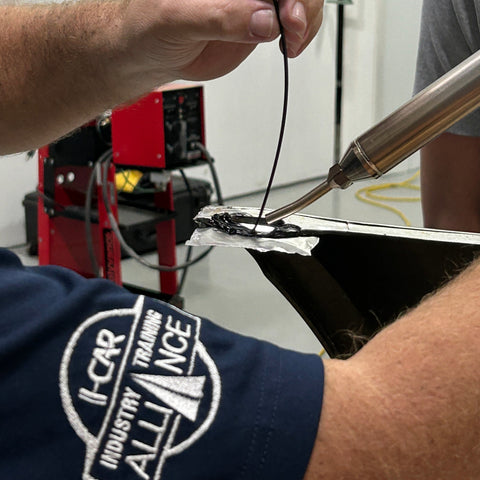

- Live Welding Sessions: Execute real repairs on sample parts using Polyvance nitrogen welders under expert guidance.

- Technique Mastery: Practice edge‑to‑edge bumper welding, slop‑tab restoration, slot and flange repairs, and fine‑tune aesthetic finishes.

- Assessment & Credential: Complete a practical exam and knowledge quiz to earn your Area22 Plastic Repair Technician certificate, demonstrating proficiency in both theory and application.

Successful trainees receive a certificate confirming their proficiency in Plastic Welding, backed by Polyvance and Area22’s industry‑recognized training standards.

Prerequisite/Requirement

- Personal Protective Equipment (PPE) listed below:

- Safety Boots

- Safety Glasses

- Welding Jacket

- Welding Gloves

- Nose Mask

Why Choose This Course

- Superior Repair Strength: Nitrogen fusion welding yields repairs that often exceed original part strength, reducing warranty claims and rework.

- Cost & Environmental Impact: Drastically lower replacement costs and minimize plastic waste by extending part life.

- Expert-Led Curriculum: Learn from instructors certified in Polyvance methods, with decades of OEM and after‑market experience.

- Comprehensive Support: Gain access to post‑course resources, including detailed plastic repair guides and material ID tools, ensuring ongoing success in your shop.

Enjoy a seamless learning experience with breakfast and lunch included, alongside detailed guidance from industry experts. Upon successful completion, participants receive personalized evaluations, valuable feedback, and certification, ensuring readiness to meet professional standards in collision repair and industrial sectors.

Equip your team with the skills to deliver lasting, high‑quality plastic repairs. Choose Area22’s Polyvance Plastic Repair Course for industry‑leading training.